Delta Technocast’s precision machining service stands out in the industry for its exceptional accuracy, efficiency, and commitment to quality. Leveraging advanced machinery and cutting-edge technology, our precision machining capabilities complement our investment casting operations, allowing us to deliver high-precision components that meet the stringent requirements of various industries.

Whether integrated with our casting services or offered as a stand-alone solution, our precision machining services ensure that each product achieves the desired specifications with unparalleled consistency and reliability. We understand the critical role that precision machining plays in the manufacturing process. Our state-of-the-art facility is equipped to handle a wide range of machining tasks, from simple to complex geometries, ensuring that every component meets the highest standards of accuracy and finish. With a focus on continuous improvement and customer satisfaction, our team of skilled professionals is dedicated to providing precision machining solutions that not only meet but exceed our clients’ expectations.

Precision machining is a manufacturing process that involves removing material from a workpiece to achieve exact dimensions and surface finishes. This is done using specialized tools and machines to create parts and components with high accuracy and tight tolerances. The process encompasses various techniques such as turning, milling, drilling, and grinding, each tailored to meet specific requirements.

Precision machining plays a critical role in the production of components across a wide range of industries, including aerospace, automotive, medical devices, and more. It ensures that each part fits perfectly into its intended assembly, enhancing overall performance and reliability. By utilizing advanced CNC (Computer Numerical Control) machines and state-of-the-art technology, precision machining allows for the creation of complex shapes and intricate details that are essential for modern manufacturing.

Precision machining ensures that parts are produced with exact dimensions and tolerances, which is crucial for components that need to fit perfectly within assemblies. The consistent quality reduces the need for rework and ensures reliable performance.

The technology enables the production of intricate and complex geometries that are often impossible or too costly to achieve with other manufacturing methods. This is particularly valuable in industries requiring highly specialized parts.

Precision machining can achieve superior surface finishes, which not only improves the aesthetic quality of the parts but also enhances their functionality, reducing friction and wear.

By precisely removing material, machining minimizes waste compared to other methods. This efficiency contributes to cost savings and environmental sustainability.

The process is highly adaptable, allowing for easy modifications and customization of parts without extensive tooling changes. This flexibility is beneficial for both small and large production runs.

Precision machining supports rapid prototyping, enabling quick development and testing of designs. This accelerates the product development cycle and helps bring innovations to market faster.

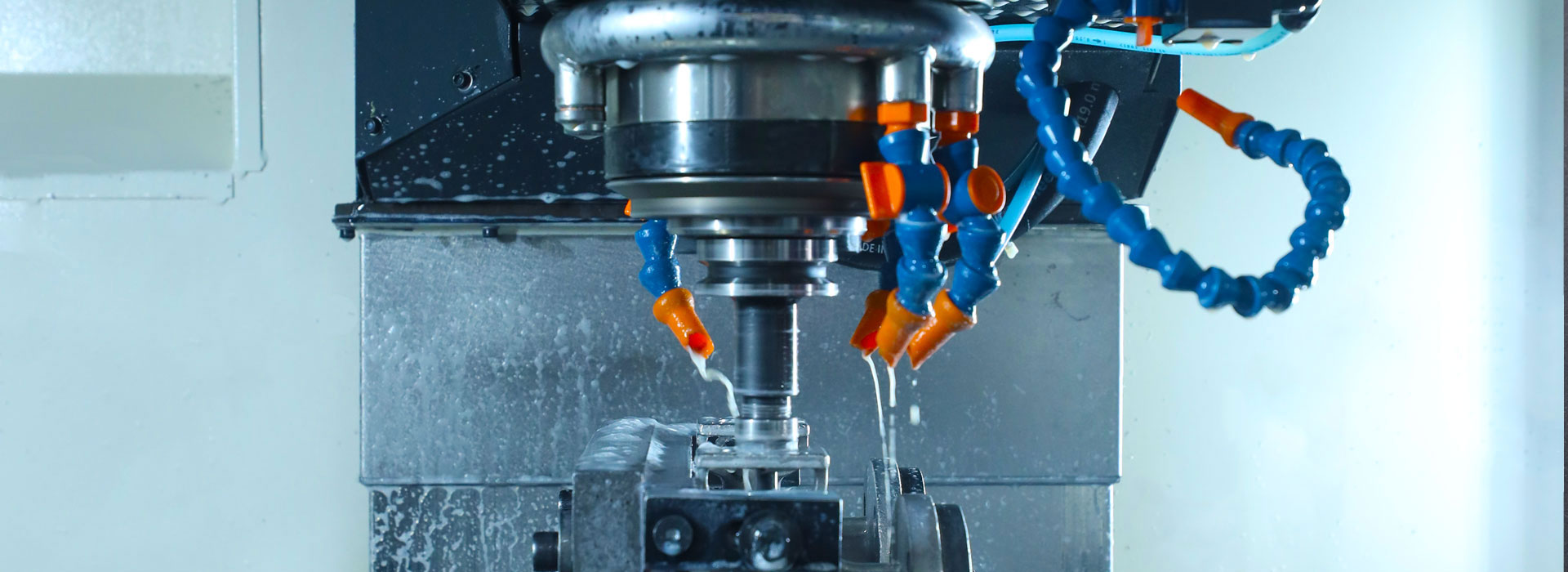

CNC Milling Machines: Our high-precision CNC milling machines handle complex geometries and tight tolerances with ease, providing versatility and accuracy in a variety of materials.

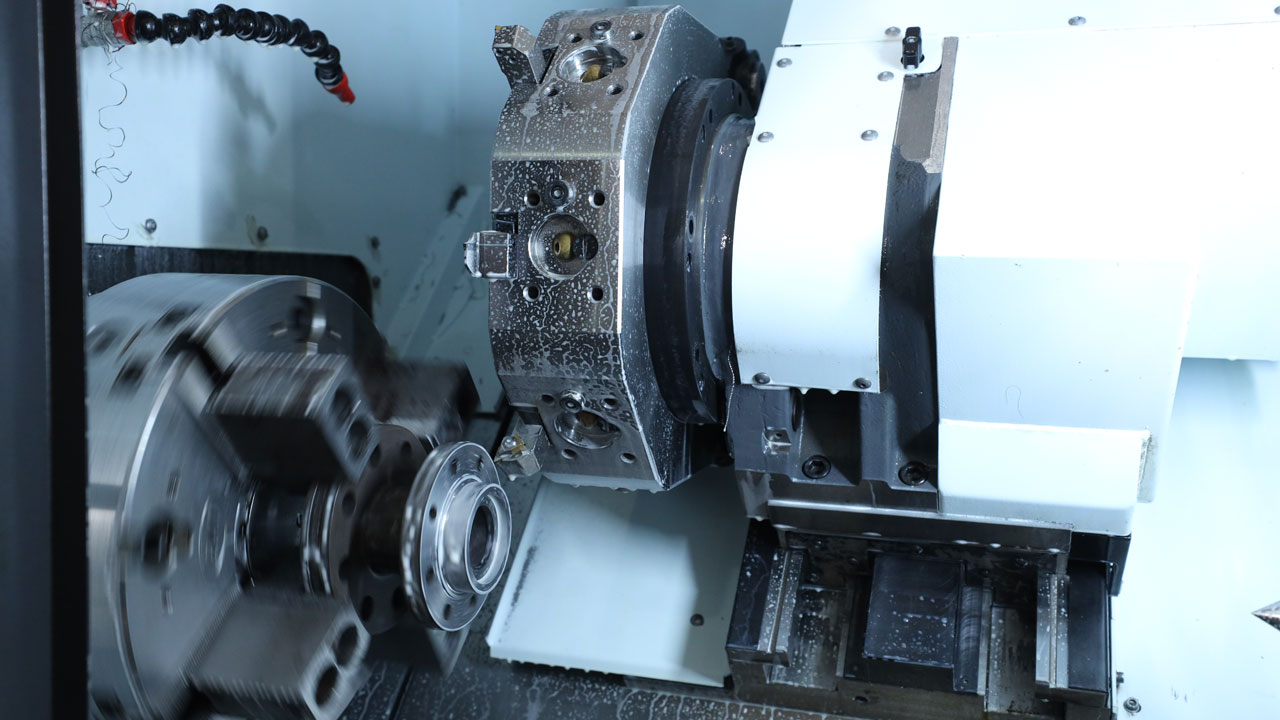

CNC Turning Centers: Equipped with advanced turning centers, we can produce intricate cylindrical components with superior surface finish and dimensional accuracy.

Grinding Machines: Our precision grinding machines ensure tight tolerances and excellent surface finishes, essential for achieving high-quality end products.

Drilling & Boring Equipment: With our advanced drilling and boring machines, we achieve precise hole placements and depths, critical for component functionality.

Inspection and Measurement Tools: We use cutting-edge inspection tools and measurement systems to verify the precision and quality of each component, ensuring adherence to specifications and industry standards.

Delta Technocast extends its expertise in precision machining beyond just supporting its casting operations. Our stand-alone machining services cater to clients who require high-precision machined components for various applications, ensuring top-notch quality and performance. Our state-of-the-art equipment and skilled machinists ensure precise and accurate machining, meeting the most stringent tolerances.

Delta Technocast’s precision machining capabilities extend to a wide range of materials, ensuring versatility and adaptability for various applications. Our expertise includes machining carbon steels such as 1010, 1020, and 1045; spring steels like 1066 and 50CrVA; bearing steels including 52100 and 440C; and tool steels such as M2, M50, D2, A2, and S7. We also excel in working with copper alloys, aluminum alloys, and various grades of stainless steel. This broad material expertise allows us to deliver high-quality, reliable machined parts tailored to meet the unique requirements of our clients.

Our precision machining services are utilized by diverse industries such as automotive, aerospace, medical, industrial machinery, and more. We understand the unique requirements of each sector and tailor our services to meet their specific needs.

Delta Technocast offers a range of finishing services to provide you with complete, ready-to-use parts. Our services include:

For processes not performed in-house, we work with carefully selected vendors who meet our stringent standards for quality and on-time delivery.

Delta Technocast is committed to delivering high-quality investment casting solutions that meet the diverse needs of our clients. Our expertise, combined with our advanced capabilities and customer-centric approach, ensures that you receive the best value and performance from your investment cast parts.

At Delta Technocast, quality is at the core of everything we do. Our stand-alone precision machining services adhere to strict quality control measures, ensuring that every part we produce meets the highest industry standards. We continuously invest in technology and training to stay at the forefront of machining excellence.

Take a closer look at the precision and quality of Delta Technocast’s precision machining service by visiting our product page. If you have specific needs or require a custom solution, our team is ready to work with you to create parts that meet your exact specifications.

Delta Technocast offers a comprehensive selection of materials and alloys to meet the diverse needs of our customers across various industries. With expertise in over 150+ different ferrous and non-ferrous air-meltable alloys, we ensure that each casting is produced using the optimal material for its intended application.

Our team of metallurgical experts assists customers in selecting the right material for their application needs. Whether it’s corrosion resistance, high strength-to-weight ratio, or specific mechanical properties, we ensure that each material choice aligns with the performance requirements of the final part.

Delta Technocast also offers capabilities for developing custom alloys and conducting research into new material solutions. Our Research and Development team collaborates closely with customers to innovate and optimize material performance for challenging applications.

All materials used in our investment casting process undergo rigorous testing and certification to ensure they meet industry standards for mechanical properties, chemical composition, and performance characteristics. This commitment to quality assurance ensures that our castings consistently meet or exceed customer expectations.

For services not performed in-house, such as specialized coatings or specific machining processes, we partner with trusted vendors who meet our strict standards for quality and reliability. This ensures that every aspect of your project is handled with the same level of precision and professionalism that defines Delta Technocast.

At Delta Technocast, we understand that every project is unique. Whether you require complex machining, specialized finishes, or intricate assembly, our team is dedicated to delivering custom solutions that meet your exact specifications and quality standards.

All operations and services at Delta Technocast undergo rigorous quality control measures to ensure consistency, reliability, and adherence to customer requirements. Our commitment to quality extends across every stage of production, from initial consultation to final delivery.

Offering castings for valves, pumps, drilling equipment, and other components used in the exploration, production, and transportation of oil and gas.

Supplying aerospace-grade castings for aircraft engines, structural components, landing gear, and other aerospace systems that demand exceptional performance under extreme conditions.

Delivering corrosion-resistant components for marine applications, designed to perform reliably in harsh environments.

Providing critical components for engines, transmissions, chassis, and other automotive applications where precision and durability are paramount.

Supplying wear-resistant parts for mining equipment, enhancing durability and operational efficiency in extreme conditions.

Providing precision-engineered components for various engineering applications, ensuring high-quality and reliable performance.